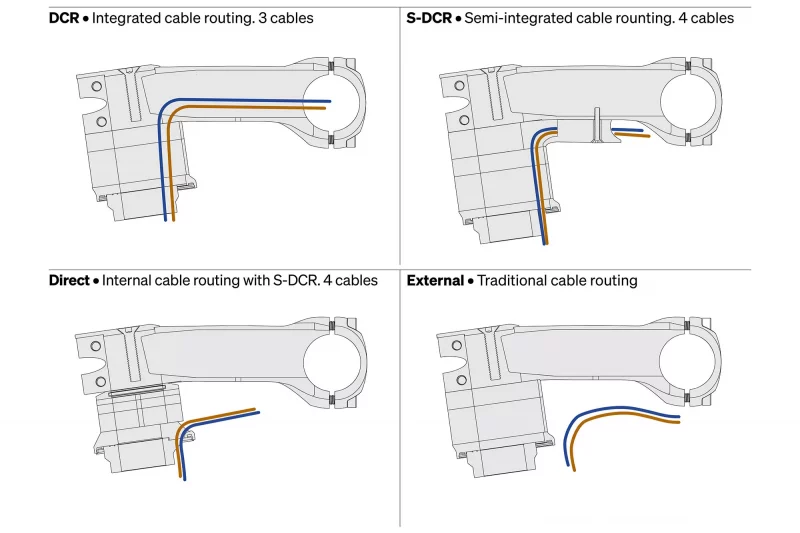

Love them or hate them, inner cable routing headsets are ripping via the bike trade like wild-fire. It’s one among a sequence of steps manufacturers have taken towards full integration. Objectives embody improved aerodynamics, improved aesthetics and, the holy grail, “clear traces”. For some, nevertheless, it’s a step too far.

Operating cables and brake hoses via the headset does, undoubtedly, tidy issues up within the cockpit. Nevertheless, headset-dependent, it does include further time spent within the work stand, and the elevated labor prices related to that. Some riders with deep pockets will, I’m certain, be joyful to pay the premium, however others are in for a shock.

For many riders, it’s their bike mechanic that has to cope with the added complexity of internally routed cables. These guys have put up with years of ever-changing “requirements” inside the bike trade, so how a lot will this actually hassle them? We contacted mechanics from Europe and the US to get their viewpoint on inner headset cable routing, and whereas a few of them did reply with a way of diplomacy, others have been reasonably extra agency of their opinion.

We despatched them the next:

“It’s you guys, the mechanics, who should cope with the appearance of inner headset cable routing that’s sweeping throughout the trade. So, what are your ideas on it? Is it factor, or a nasty factor? Are you having to cost your clients extra for headset bearing replacements, brake bleeds, cable replacements, and so forth? Is it actually that rather more trouble, or is it straightforward sufficient when you’ve completed one or two? Would you’ve it in your private bike if, in some parallel universe, you weren’t liable for the upkeep of your individual bike?”

Bike Mechanics’ Take On Inside Headset Cable Routing

Joergen at Parallel Handbuilt – Netherlands

What are your ideas on totally inner, built-in cabling?

They’re high-quality, every part’s gonna be high-quality, simply pay me € 350 to swap your € 25 headset bearings… lol.

I feel it’s principally high-quality. Usually sufficient it does complicate wrenching on a motorbike, if the “wrenching” to be completed includes getting deeper into the bike, the body particularly. Some designs in the marketplace require partial or full disassembly of a motorbike to do common (albeit not usually completed) upkeep equivalent to changing headset bearings. Some bikes with totally inner and built-in cabling which might be ridden in locations in circumstances that wish to eat headset bearings commonly, like cyclocross or mountain bike, needs to be prevented in the event you’re asking this mechanic.

Is it factor, or a nasty factor?

I don’t suppose it’s both. If a buyer is especially enthused about having all their cables, or in all actuality, simply two hydraulic hoses, tucked away neatly of their frames, then it’s a terrific factor! If a consumer likes DIY upkeep, sustaining their bike extra usually, or simply inexpensive upkeep, then it isn’t factor. When a motorbike is offered to a buyer and the potential €1000 additional per yr on built-in cabling-related upkeep has not been communicated clearly, that may be very a lot a nasty factor.

Am you having to cost clients additional?

I don’t cost clients “additional”, however I’m undoubtedly pressured to cost clients extra labour when servicing a motorbike with this kind of cabling and doing restore or upkeep associated to, or behind the inner routing. Which may be me being pedantic, nevertheless it’s an vital element.

A easy headset bearing substitute, one thing that could be as low-cost as € 50-70, will be 4 to 5 occasions as costly on some inner cable designs due to the need to de-cable the bike and re-bleed the brakes after the set up.

Is it actually that rather more trouble, or is it straightforward sufficient when you’ve completed one or two?

I imply, I’m a motorbike mechanic, it’s my job to repair the bike in entrance of me. I wouldn’t describe the repairs completed on these extra difficult bikes as an even bigger “trouble”, it’s simply way more work and due to this fact extra price for the consumer. To be fully clear, there are many bikes in the marketplace right now with a lot easier cabling which might be an enormous headache for different causes. Part design and integration is every part.

Is it tougher that so many bikes use barely completely different options?

Annoying. Annoying is the phrase you’re on the lookout for. When a model “develops” a brand new resolution for higher Cable Integration™ however doesn’t, or can’t present good, unbiased after-sales help, a comparatively easy and painless (albeit costly) restore turns into a whole headache for me and my consumer. I’m not naming names, however y’all know who I’m speaking about. Some manufacturers have very weak documentation as after-sales help, and in these instances, it’s way more troublesome, however that’s simply since you want particular, proprietary parts however can’t discover an article quantity for instance.

Would you’ve it in your private bike if you weren’t the mechanic?

No. Fairly truthfully, I don’t just like the aesthetics of fully built-in cabling. I really like a well-cabled bike, tight curves in good proportions to the opposite cable(s) and size of the headtube, with a easy entrance into the downtube or onto the underside of the downtube. I really like the convenience of upkeep, whether or not I’m doing it myself or paying another person to do it. Let me be clear right here, I hate a rat’s nest on the entrance of a motorbike identical to the remainder of y’all, however two neat and tidy cables poking out from underneath the bar tape, snaking into the body… It simply jogs my memory {that a} bicycle could be a murals and design, but in addition very a lot a software and a method to an finish.

Nick Tanner, Bspoke Cycles – Scotland

Marmite. Sums it up for me.

There’s one thing good, refined and ‘up-to-date’ about built-in headsets and cabling, however I feel this solely actually applies to the patron. We have now clients curious in regards to the lack of seen cables and which have historically been there for many years, they usually do, nearly with out fail, ask ‘is it more durable or dearer to take care of’.

Integration lends itself to dearer part substitute; in the event you’re paying double the time for a headset service, it is smart to pay for a extra sturdy headset/bearings, which can be 3 occasions what you’d usually pay, but when taken care of will typically outlast the bike. This additionally encourages some skilled clients to take extra care of their bike as they turn out to be conscious of the elevated service prices. These shopping for for the primary time haven’t any benchmark in opposition to which to evaluate the newer, dearer prices.

Sure, I’d have full integration on my bike as I just like the clear look, and ease of mounting lights, GPS and so on, however I don’t cost myself for my time concerned in placing my bikes collectively. Having mentioned that, as an ex-SRAM technician I’ve very excessive requirements in product and repair expectation, and for my part the design of many built-in headset parts isn’t the place it could possibly be; spacers don’t line up, there are gaps between stems and stem caps; if like me you’ve a bit of motorbike construct OCD it’s irritating when components simply don’t match effectively.

We have now clients convey us bikes to assemble that they’ve purchased on-line or elsewhere, and infrequently corners have been lower with manufacturing unit meeting or lack of QC; no lubrication, cables/hoses too quick and so on. This provides additional time to a boxed bike construct, and sure, we cost extra consequently. We all the time quote a worth earlier than beginning any work in order that the client has no surprises. We typically take in the price of an additional barb or compression becoming when swapping brakes from Euro to UK setup, as these are not often provided within the vary of bikes we see. It will depend on the dimensions of the job and what the bike is in for.

In my view the worst facet of built-in headsets is the default Euro setup; hoses and cables tackle ‘reminiscence’ from the manufacturing unit and boxing, and are sometimes broken the place there isn’t sufficient clearance inside the headset. Carbon frames are usually OK because the tube joints are a lot bigger voids, however alloy frames have such small holes on the joints that the cables or hoses usually jam up. I’ve had one severed brake hose, within the field! From my perspective as a mechanic when constructing a brand new bike, I would like the cables and hoses provided pre-cut, however not noted of the body. There are a number of secret workshop methods I exploit to make changing built-in cables simpler and faster than adjusting and/or changing these poorly put in on the manufacturing unit.

As for aero on street bike headsets, what number of common riders will expertise the watt-saving advantages of hidden cables? What number of will discover the bar/stem integration measurement is unsuitable and require a change? What number of small IBDs would take in the price of a £500+ one-piece bar/stem combo swap? Will the client pay one other £500 on prime of the bike price? Sadly, the pandemic remains to be affecting product provide, and in some instances built-in headset parts are unavailable till subsequent yr, which means a motorbike that wants for instance a 10mm stem change both doesn’t promote, or shall be a sub-optimal match for the client for months to return.

Headset integration is clearly right here to remain, and I feel in time the designs will enhance, and with luck, extra thought shall be given to the practicalities of their becoming and servicing, and the mechanics who do the onerous graft. I’m a fan of the idea and the looks, however I don’t but take pleasure in engaged on them.

Václav Svatoš, Unbiased Bike Mechanic – Czech Republic

So, what are your ideas on totally inner , built-in cable routing?

It is just trendy and an evolution of bicycles and clear design and perhaps some watt saving like aerodynamics. From a technical aspect, it’s horrible for mechanics, customers, and designers of parts and components like hydro hoses.

Is it factor, or a nasty factor?

It’s good if aero is vital and it’s good to save watts. It provides time when it’s good to change place of stem or change headset bearings or it’s good to take off bars for touring. All service on the bike with hoses contained in the bars, stem, and headset is extra difficult and way more costly.

Are you having to cost your clients additional (or extra usually) for headset bearing replacements, brake bleeds, cable replacements, and so on?

Sure, all is dearer and I like to recommend to clients on new bikes to vary sub-optimal headset bearings (BMC on so costly bikes use headset bearings for $10 with a horrible lifetime) for chrome steel bearings with good high quality seals. If it’s good to change bearings, it’s a horrible job when you have to lower brake hoses, typically change one hose (you’ll be able to normally use the previous rear for entrance brakes and also you want new one for rear). Altering the rear brake hose is usually not straightforward (it’s a query in regards to the BB space). If it’s good to change headset bearings, it’s typically a more durable job than constructing a brand new bike (you have to clear up every part, take all of it off, after which construct once more from zero.

Is it actually that rather more trouble, or is it straightforward sufficient when you’ve completed one or two?

Sure, it’s extra difficult. Sure, in the event you make the identical bikes many times, you understand how to try this rapidly. However the job time and job steps are the identical.

Is it tougher that so many bikes use barely completely different options?

Sure. There’s no actual customary of this, some firms use conventional headset bearings and a few D-shape steerer tubes and with out extra space for hoses. (You need to overlook mechanical groupset!) Some firms could overlook to make a gap within the steerer tube for the entrance brake hose after which solely settle for the FSA system with hose going into the steerer from the highest! That’s probably the most horrible concept, and the hoses are bent greater than 90° in such a small area!

Would you’ve it in your private bike if, in some parallel universe, you weren’t liable for the upkeep of your individual bike?

On my bike… for my cash? No by no means. I’ll have a 100% purposeful bike with out feeling the rear brake hose in the event you flip the bars. I would like bikes with straightforward removing of the fork to service the headset, change a headset spacer, for simple for touring, straightforward to vary handlebars or change levers, and so on. So, no.

James at Analog Cycles – Vermont

At Analog, all we do is construct journey bikes. Something that makes a motorbike more durable to discipline service is unhealthy for the client out on tour, and any gap within the body that doesn’t have to be there’s a place for water to get in and likewise a spot the place the body is weaker. This has been born out by testing bikes with and with out inner routing holes in managed affect and fatigue checks carried out in Taiwan for our sister firm Tanglefoot Cycles.

Inside cable housing additionally bangs round in a body, which makes clients suppose they’ve a body crack when actually it’s simply crappy engineering. I’d be extra with the inner headset routing if there was a full size tube to seize the housing the complete means. This might remove banging noises, water egress, and the PITA of fishing a cable out. Sure there are good strategies on the market for getting a little bit of cable via, however these don’t all the time work (i.e. typically a buyer has pulled all of the cables out in a DIY effort, and so on) and fishing a cable via a body is nobody’s concept of time. Moreover, in the event you have a look at how a lot put on a little bit of housing causes on a paint job to the purpose of body put on, even on a metal bike, one should marvel a few cable housing smacking and rubbing in opposition to a paint-less, hidden steerer tube made from plastic. Looks as if an accident ready to occur.

So, what are your ideas on totally inner, built-in cable routing? It’s additionally pointless for bikes that not often are transferring at peloton speeds.

Is it factor, or a nasty factor? Nice for loopy street bikes I assume, professional bikes…

Are you having to cost your clients additional (or extra usually) for headset bearing replacements, brake bleeds, cable replacements, and so on? We cost a premium for all inner routing. Headset routing isn’t more durable than body routing, nevertheless it takes extra time so it’s good to cost extra.

Is it actually that rather more trouble, or is it straightforward sufficient when you’ve completed one or two? Simple sufficient, the problem isn’t ease of use on a workstand.

Is it tougher that so many bikes use barely completely different options? After all it’s a ache within the ass. How might it not be? New requirements imply new tooling, extra training for workers, extra time spent on youtube the primary few go rounds.

Would you’ve it in your private bike if, in some parallel universe, you weren’t liable for the upkeep of your individual bike? Hell no. Essentially the most I’d do can be inner routing with a brazed in place brass tube on a gravel or street bike prime tube or chainstay. I don’t suppose the headset routing seems good, it seems low-cost, like a Walmart bike resolution to not braze on cable guides. What would Pacific do? Inside routing! Lots of these items is only for producers to tout marginal weight financial savings over final yr’s mannequin. Should you eliminate downtube cable ports or housing bosses, you progress the port to the headset, and instantly your body is X quantity of grams lighter. It’s all a rip-off, there is no such thing as a legit purpose exterior of aerodynamics to maneuver the routing to the headset. So, in the event you see this routing on something however a professional degree bike, and also you suppose it’s rad, you’ve been had.

Mitch Graham of BioWheels – Madeira, OH

I assume we take the strategy that it doesn’t do us a lot good to complain about what the trade does with inner routing or new requirements on the bread-and-butter bikes that we promote and repair. It’s what it’s. If most clients are in favor of those options (many are on the lookout for full integration), then we’ve to be. The typical worth for a motorbike we promote is $6000 which signifies that now greater than half of the bikes we promote to of us have totally inner routing. We’re used to coping with them, they usually undoubtedly get simpler the extra you’re employed on them (particularly in case you are seeing the identical fashions in entrance of you time and again.) Wanting again now into our workshop, each bikes being tuned up have full inner routing. So increasingly more service bikes coming in are inner. We cost hourly for service, so we run the clock as soon as we begin work on a motorbike, and invoice for our time. So sure we’ve to cost extra as a result of these bikes are all the time going to take longer to service than the earlier era.

Would I personally select a motorbike with conventional routing or totally inner? Nice query. I assume since I would like the brand new Moots CRD street bike greater than I would like the earlier mannequin – I must say totally inner for me! They simply look superior.

What impact does inner routing have on bike becoming? There isn’t sufficient time throughout a motorbike match to swap a completely built-in bar/stem out, in order that job normally will get pushed to the service division of our store, or the match consumer’s store again dwelling. We use a fully-adjustable GURU becoming bike for the precise bike match, so we’re capable of get the client their measurements from that (which then would get transferred onto their bike).

Felix Wolf, Mild Wolf Studio – Germany

What are your ideas on totally inner, built-in cable routing? Everyone desires it, no one’s needing it, however we’ll do it in any case.

It might probably solely be an aesthetic factor since there’s no technical benefit from our perspective.

We see far more disadvantages.

Is it factor, or a nasty factor? It’s a pattern of this time.

As a customized bike builder, we’re within the fortunate place to fastidiously choose our merchandise and naturally persuade our clients for the very best resolution.

Most bikes we construct these days include AXS or Di2 shifting. So we’ll have solely two brake hoses. Our second benefit may be promoting bikes to customized match. Thus, we will lower these two hoses precisely to the size wanted by figuring out spacer stack, stem and handlebar specs. This manner we will obtain a really clear look with out squeezing hoses although small components.

So most bikes don’t include full integration. But when it comes with inner routing we’ve strict guidelines:

We’re not constructing bikes with 2x mechanical drivetrain and built-in cables – 1x solely in some uncommon instances. We simply need to keep away from the unfavorable impact of stiff cables effecting your steering, and to reduce the chance of rattling. To conclude: we solely use techniques that actually work effectively and will be actually choosy to keep away from downsides for us and the client.

Are you charging our clients additional (or extra usually) for headset bearing replacements, brake bleeds, cable replacements, and so on?

Truly we’re not charging additional or extra usually, we simply cost per hour within the workshop. And a headset bearing substitute took minutes within the previous days. Now it’s hours to open and re-bleed two hoses and maybe additionally must take away the BB for rerouting the rear one – relying on the brake system. I assume most clients don’t take that under consideration and shall be shocked by the excessive workshop invoice. There are some inner routing techniques on the market that depart bearings uncovered. I guess it will have an effect on headset lifetime. However for us it’s easy – we simply don’t promote bikes with that form of built-in resolution.

Is it actually that rather more trouble, or is it straightforward sufficient when you’ve completed one or two?

In most occasions, its a ache within the ass and the mechanic must develop a 3rd arm. However in fact, only some bike mechanics are used to it by engaged on built-in options day by day. And with extra bikes coming with these integrations, we’ll get used to it and evolution would possibly assist with a 3rd arm sooner or later. We’re in a snug place once more with a boutique workshop, fastidiously assembling every bike. If a construct wants any longer – we’ll have the time and endurance.

Is it tougher that so many bikes use barely completely different options? We don’t see so many alternative options. There’s an even bigger higher bearing, a carved higher race, split-able spacers and a stem and handlebars with numerous holes. They could differ specifically form, however the system used is all the time quiet related.

Would you’ve it in your private bike if, in some parallel universe, you weren’t liable for the upkeep of your individual bike? To be trustworthy, I’m simply planning a brand new journey with every part {that a} bike store used to hate: totally built-in cables and proprietary components. You guessed it proper – as a result of it seems cool!

Evan Robinson of Regular State Cycles – Pittsburgh

The present pattern for working hoses and cable/wires via the headset is nice. Making a clear cockpit makes any high-end street bike look way more trendy. If there are marginal positive factors from having the hoses contained in the headset, I’m right here for it.

However I feel it’s prison, completely prison, for this to be on lower-end and mechanical bikes. Oversize headset bearings require substitute much less usually. Entering into the top tube to scrub and grease the interfaces between the bearings and the body is slightly ache within the ass, however on many high-end bikes, not a deal breaker.

I had a buyer that did 10,000+ miles a yr in western Pennsylvania and wanted a headset after two seasons. The bike was due for an overhaul in any case, so different requirements absorbed the price. I additionally suppose apply as a mechanic to exchange the cable housing reasonably than the interior cables alone is an expert apply, and now that turns into a particularly costly job on an entry-level bike.